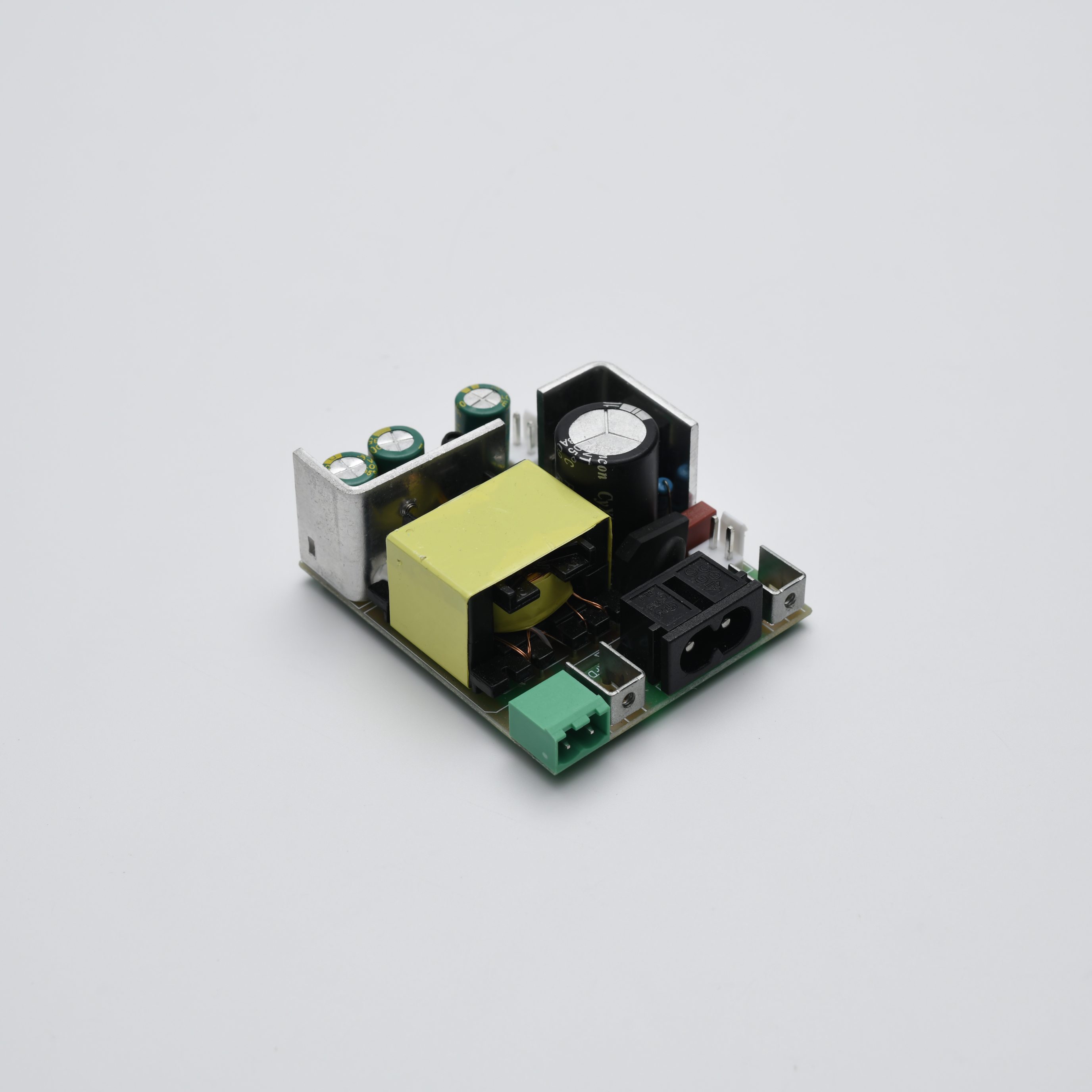

Product Information

| Model: | HJXY-D300 |

| Type: | Ac~Dc Power Board |

| Custom Processing: | OEM |

| Certification: | CE / ROHS |

| Whether to Customize: | Parameters can be customized according to needs |

Product Specifications

| Input Voltage: | AC100~240V |

| Input Frequency: | 50/60Hz |

| Output Voltage And Current: | 20V5A 24V4.15A 28V3.5A 30V3.3A |

| Output Power: | 100W |

| Work Efficiency: | ≥85% |

| Working Temperature: | -20℃~+50℃ |

| Storage Temperature: | -20℃~+80℃ |

| Humidity: | 10%~90% RH |

| Modulation Mode: | PWM Formula |

| Multiple Protection Functions: | Overvoltage protection, short circuit protection, overload protection, temperature protection |

The HJXY-D300 is a cutting-edge industrial-grade device designed for high-performance applications. Below are its key features with technical specifications:

The HJXY-D300 boasts ±0.01mm positioning accuracy with a repeatability of ±0.005mm, achieved through its advanced servo motor system (400W, 3000rpm). The linear guideways feature C3-grade precision ballscrews with a lead error of ±5μm/300mm, ensuring micron-level operational consistency.

Constructed with FC-30 cast iron (tensile strength: 300MPa) and hardened steel components (HRC 58-62), the frame demonstrates a natural frequency of 120Hz, effectively dampening vibrations. The IP54-rated enclosure protects against particulate contamination and splashing liquids.

Incorporating a closed-loop thermal compensation system, the D300 maintains positioning accuracy within ±2μm/°C across its operational temperature range (5-40°C). The linear scales feature a thermal expansion coefficient of 0.9μm/m°C, significantly lower than standard steel (11.5μm/m°C).

With acceleration capabilities reaching 1.5G and maximum traverse speeds of 60m/min, the D300 achieves rapid positioning while maintaining smooth motion (jerk controlled below 20m/s³). The servo system delivers a torque ripple of just ±1.5% at rated speed.

The 32-bit RISC processor executes motion commands with 125μs cycle time, supporting 512-axis synchronization via EtherCAT (100Mbps). The control resolution reaches 0.1μm with a following error of <5μm during contouring operations.

The regenerative braking system recovers up to 85% of kinetic energy, reducing power consumption by 30% compared to conventional drives. Standby power is maintained at <15W, with a power factor correction of 0.98 at full load.

Applications

Digital speakers, machine equipment, etc

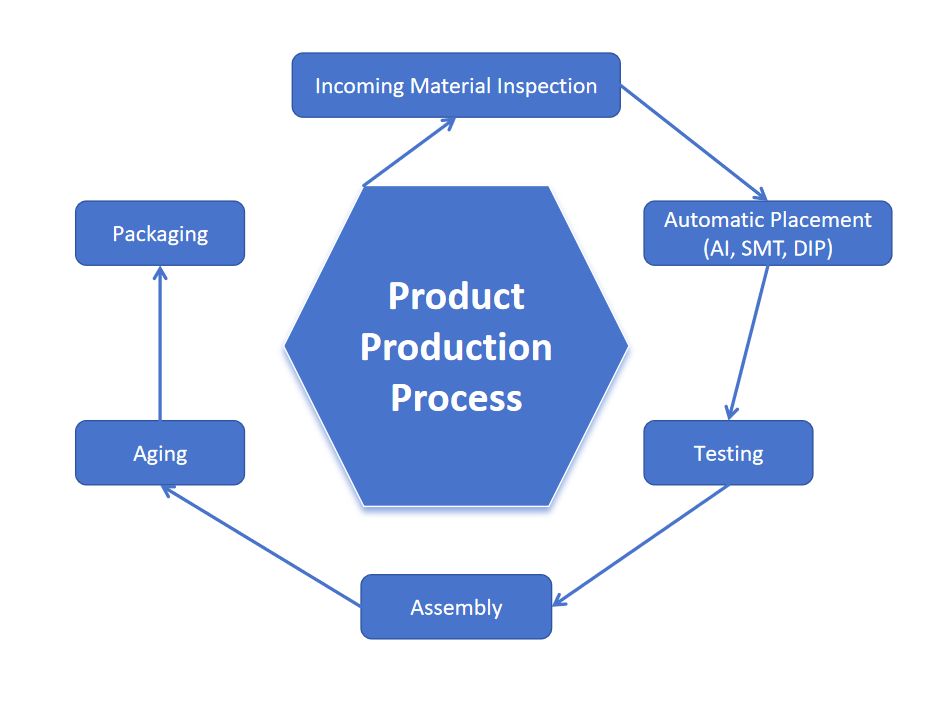

Product Description

What is Ac~Dc Power Board?

An AC-DC Power Board is a circuit board or module that converts alternating current (AC) into direct current (DC). It is commonly used in various electronic devices and applications to transform electrical energy from the grid or other AC sources into stable DC power for proper operation of the equipment. These power boards are widely applied in household appliances, computer equipment, telecommunications devices, industrial automation, and more. They feature efficient conversion, stable output voltage, and protective functions to ensure the safety and reliability of connected devices.

Key Features:

1.Efficient Conversion: Efficiently converts alternating current (AC) to stable direct current (DC), improving energy utilization.

2.Stable Output Voltage: Provides stable DC output voltage to ensure consistent operation of connected devices.

3.Multiple Protection Functions: Includes overload protection, overvoltage protection, and short circuit protection to ensure safety for devices and users.

4.Compact Design: Compact size suitable for various space-constrained applications.

5.Wide Application Range: Widely used in household appliances, computer equipment, telecommunications devices, and industrial automation.

6.Reliability and Durability: High-quality components and design ensure long-term stable performance and durability.